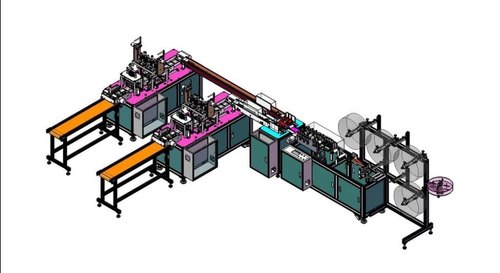

Material Preparation:

Matrics solution N95 masks are typically made from multiple layers of non-woven polypropylene fabric. The machine starts by unwinding rolls of the fabric, which then goes through a series of processes like unwinding, cutting, and shaping to create individual mask components.

Material Preparation:

N95 masks are typically made from multiple layers of non-woven polypropylene fabric. The machine starts by unwinding rolls of the fabric, which then goes through a series of processes like unwinding, cutting, and shaping to create individual mask components.

Meltblown Fabric Production:

Meltblown fabric is a critical layer in N95 masks that provides the high filtration efficiency. The machine includes a meltblown fabric production module where the raw material, usually polypropylene, is melted and extruded through a spinneret to form microfibers. These fibers are then collected and compressed to create the meltblown fabric.

Mask Forming:

The machine uses various techniques such as ultrasonic welding, heat sealing, or adhesive bonding to assemble the different mask components. These components include the outer layer, inner layer, and the meltblown filter layer.

Nose Clip and Ear Straps:

The machine incorporates processes to attach a malleable nose clip to the top edge of the mask, allowing it to be shaped to fit the wearer's nose. It also attaches elastic ear straps or headbands to secure the mask in place.

Quality Control:

Throughout the manufacturing process, quality control measures are implemented to ensure that the masks meet the required standards. These include testing the masks for filtration efficiency, breathability, and overall integrity.Meltblown Fabric Production: Meltblown fabric is a critical layer in N95 masks that provides the high filtration efficiency. The machine includes a meltblown fabric production module where the raw material, usually polypropylene, is melted and extruded through a spinneret to form microfibers. These fibers are then collected and compressed to create the meltblown fabric.

Mask Forming:

The machine uses various techniques such as ultrasonic welding, heat sealing, or adhesive bonding to assemble the different mask components. These components include the outer layer, inner layer, and the meltblown filter layer.

Nose Clip and Ear Straps:

The machine incorporates processes to attach a malleable nose clip to the top edge of the mask, allowing it to be shaped to fit the wearer's nose. It also attaches elastic ear straps or headbands to secure the mask in place.

Quality Control:

Throughout the manufacturing process, quality control measures are implemented to ensure that the masks meet the required standards. These include testing the masks for filtration efficiency, breathability, and overall integrity.