Define Goals and Objectives:

Matrics solution determine the specific goals and objectives for the fulfillment center. This includes factors such as order processing capacity, inventory storage capacity, order accuracy, and turnaround time.

Site Selection:

Choose an appropriate location for the fulfillment center based on factors like proximity to major transportation routes, availability of labor, access to suppliers, and customer base.

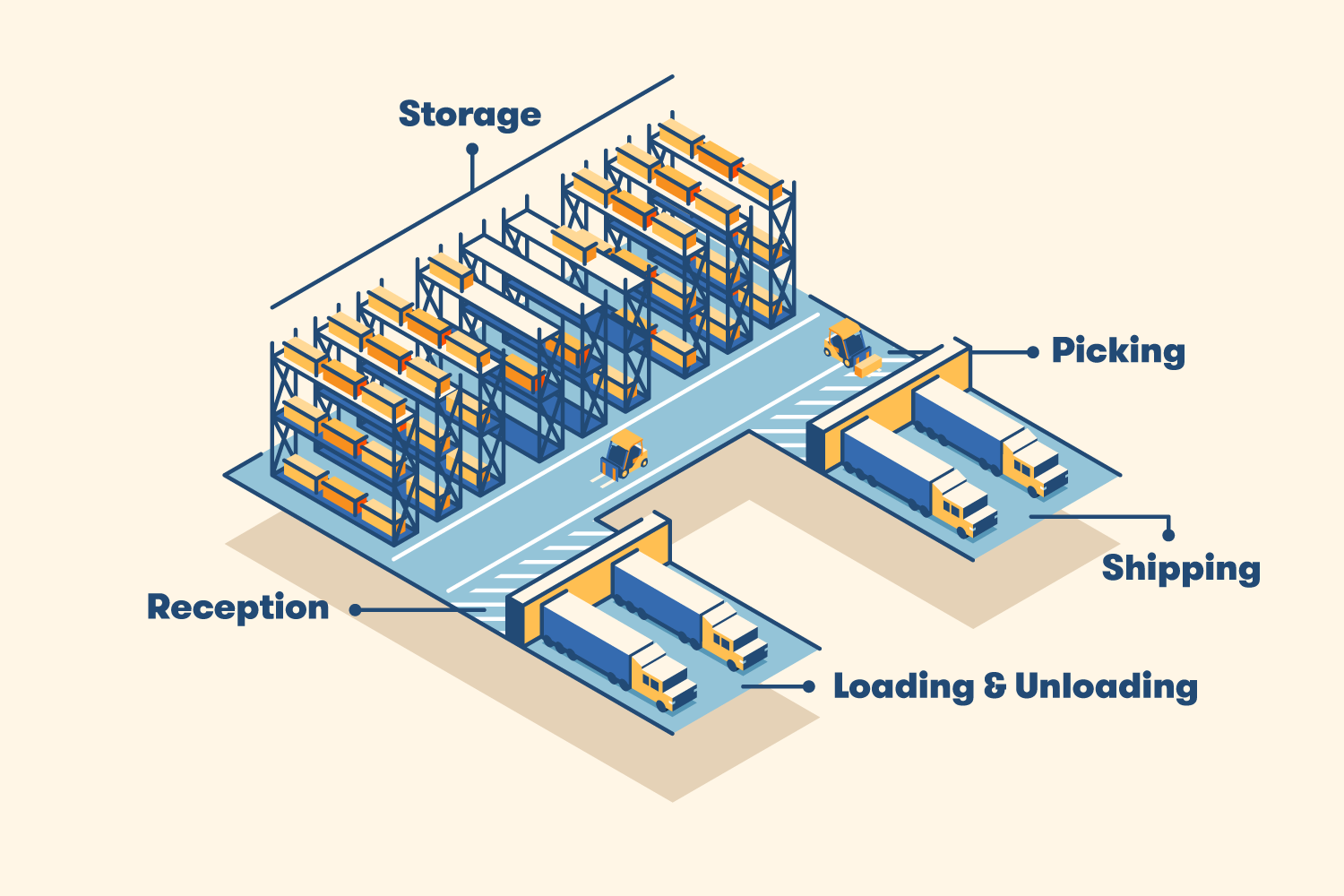

Facility Layout and Design:

Develop an efficient layout for the facility, considering the flow of goods from receiving to storage, picking, packing, and shipping. Optimize the layout to minimize travel time, improve productivity, and maximize storage capacity. Consider using automation technologies like conveyor systems, robotic picking, and automated guided vehicles (AGVs) to enhance efficiency.

Storage Systems:

Determine the most suitable storage systems for your inventory. This may include traditional pallet racking, shelving, or automated storage and retrieval systems (AS/RS) for high-density storage. Consider factors such as product dimensions, weight, turnover rate, and accessibility requirements when choosing the storage systems.

Material Handling Equipment:

Select the appropriate material handling equipment for the fulfillment center. This may include forklifts, reach trucks, pallet jacks, and order pickers. Ensure that the equipment is capable of handling the inventory efficiently and safely.

IT Infrastructure:

Implement a robust and scalable IT infrastructure to support order processing, inventory management, and tracking systems. This includes warehouse management systems (WMS), barcode scanning technology, and integration with e-commerce platforms.